Pig Iron

Coastal Exim

Pig Iron

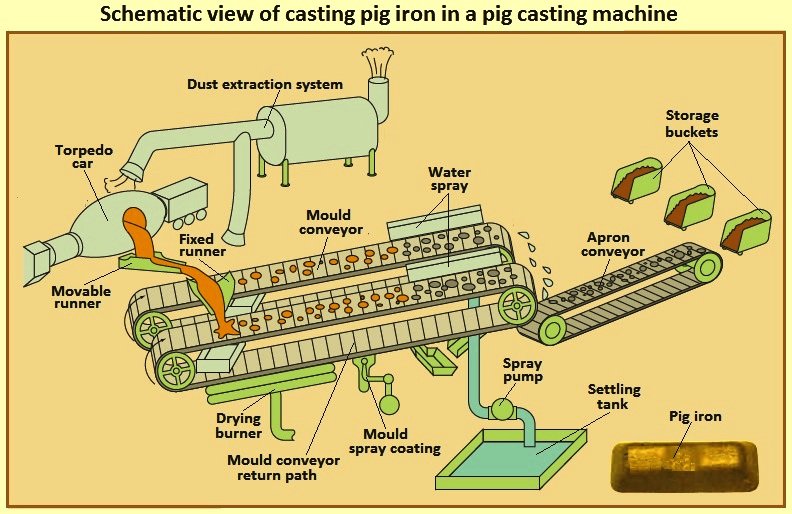

Pig iron is the intermediate product of smelting iron ore with a high-carbon fuel such as coke, usually with limestone as a flux. It is the molten iron from the blast furnace, which is a large and cylinder-shaped furnace charged with iron ore, coke, and limestone. Charcoal andanthracite have also been used as fuel. Pig iron has a very high carbon content, typically 3.5–4.5%, along with silica and other constituents of dross, which makes it very brittle and not useful directly as a material except for limited applications

Pig iron is produced in two categories, to conjugate with diversified fields. These are:

- Basic grade – This is the basic form and has a very minor presence of silicon and manganese, which is less than 1%. Along with it, the trace amounts of phosphorus and sulfur are also present.

- Foundry grade – This is known for its higher content of silicon that ranges between 1.5% and 3.5%. However, the presence may also soar up to 4.25%.

Attributes of Pig Iron

Pig iron has limited applications but support in diversified fields. The features of pig iron are as follows:

- It is wear-resistant and hard.

- It is brittle and mildly fusible.

- In comparison to steel, it has a lower melting temperature, 1200° centigrade.

- Elongation ranges between 0% and 0.5%.

- Hardness varies from 250 BHN to 450 BHN.

- Tensile strength is from 25 kNs to 50 kNs.